Loading... Please wait...

Loading... Please wait...What Parts are Needed for Bottling Line Conveyors and Rotary Turntables?

Posted by Krys Beal on 19th Mar 2019

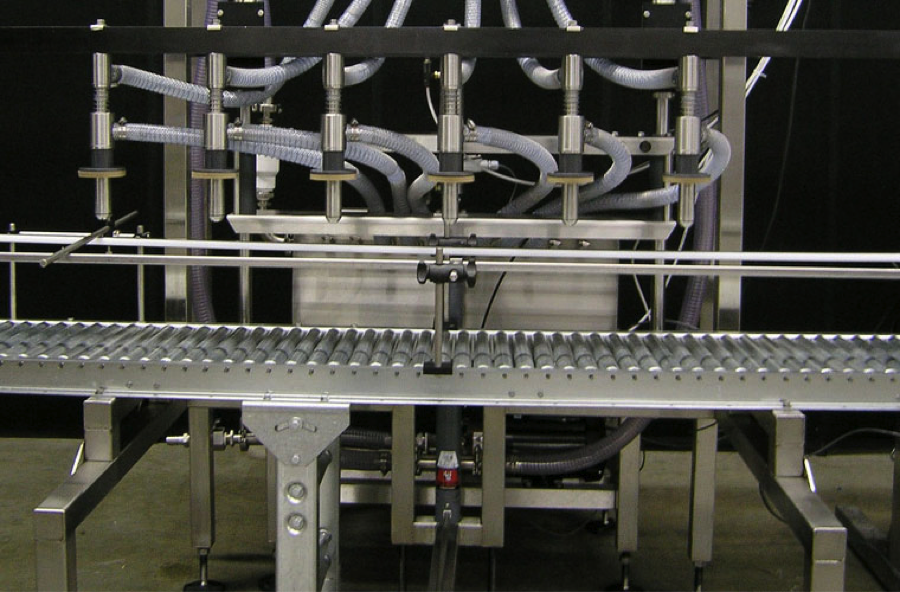

There are many components in bottling machine conveyors and rotary turntables that keep them efficient. Over time they can experience wear, and will require replacements. However, many production line operators may not be aware of some of these parts, and subsequently may not realize that weak components are making their lines less efficient.

Common Bottling Line Conveyor and Turntable Parts

Liquid filling system conveyors rely on many different parts to run and maintain efficiency. Some of the common conveyor and turntable parts include:

- Assemblies

- Brackets

- Chains

- Gear boxes

- Motors

- Drives

- Rails and wear strips

- Sprockets and bearings

Assemblies comprise the individual sections in each conveyor, including center and turn sections that connect to form a specially designed conveyor system. Brackets hold the machinery together, securing railing. Chains carry the containers down the conveyor, with varying levels of friction. Gear boxes, motors and drives make sure the conveyor runs at optimal speed, maintaining efficiency. Railing, on the other hand, keeps the containers on the conveyor, eliminating the risk of products falling off. Sprockets and bearings, in the meantime, keep the conveyor moving consistently along with the motor and drive parts.

Rotary turntables, while not as complex as larger conveyors, operate using some of the same parts, mainly brackets, rails and wear strips. Turntables are likely to experience wear much like conveyors, and packaging line owners will occasionally need to replace these parts to avoid costly breakdowns and downtime.

Together, all of these parts work cohesively to keep packaging lines working the way they should.

Perform Preventative Maintenance Checks

With all of the individual parts in mind, it's important to regularly inspect liquid filling conveyors and rotary turntables. If packaging line operators catch nonfunctional components in time, it can save facility owners both money and time spent on more extensive repairs. The breakdown of one part of a liquid packaging system can result in detrimental downtime, and keep the whole production line nonfunctional until it's repaired.

If you are unsure about which parts you need to replace in your liquid packaging line, contact E-PAK today . We will help you understand what specific components your conveyor or rotary table will need to run at maximum efficiency, and can schedule field service for our liquid filling machinery as well.