Loading... Please wait...

Loading... Please wait...Liquid Filling Machine Cost Explained: 8 Factors That Affect Pricing

Posted on 29th May 2025

Before purchasing liquid filling equipment, you have to do your research so you can make an informed decision.

One of the most important things to consider is cost. The price of a liquid filling machine can vary widely based on a number of variables, including the level of automation, the type of liquid being filled, production requirements, and other specialized needs.

Whether you’re a small business looking for a starter machine or a large-scale manufacturer needing high-speed, high-volume production, there’s a liquid filling machine solution to match your budget and goals.

How Much Does a Liquid Filling Machine Cost?

The cost of a liquid filling machine can range from a few hundred dollars for basic, manual units to tens of thousands of dollars for fully automated, high-capacity systems.

Entry-level tabletop models may start at the lower end of the spectrum and are ideal for small batch runs or startups. These machines are compact, user-friendly, and require minimal setup, making them a cost-effective entry point for businesses testing new product lines or operating at a smaller scale.

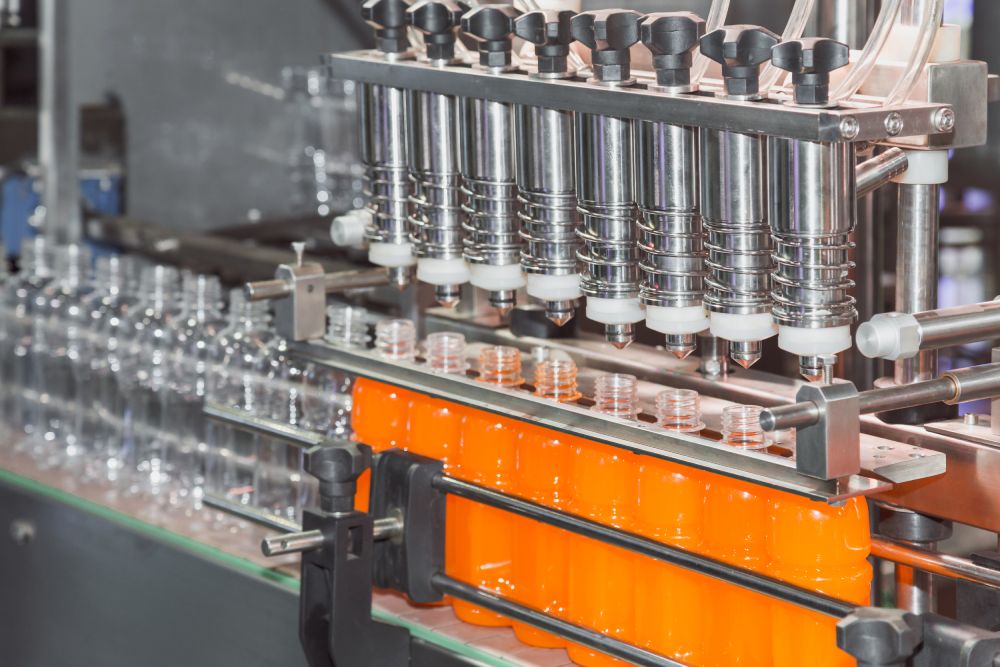

On the other hand, complex production lines designed for continuous, high-speed operations in industries like pharmaceuticals, cosmetics, or beverages often fall at the higher end of the pricing scale. These machines are engineered for long-term performance, advanced automation, and seamless integration into broader packaging systems. They may include multiple filling heads, inline cappers, conveyors, and real-time monitoring systems to ensure maximum efficiency and product consistency.

It’s also important to note that these are general ranges, and actual pricing depends heavily on customization, capacity, and application-specific requirements. You should also account for additional costs such as installation, training, maintenance, and any necessary certifications when creating a machine budget.

8 Factors That Influence the Cost of a Liquid Filling Machine

Several factors impact the cost of a liquid filling machine, and understanding these can help you determine the best equipment fit for your needs and budget.

1. Level of Automation

Manual, semi-automatic, and fully automatic machines come with different price points.

Manual fillers are the most affordable and require an operator to perform most of the filling tasks. They are suitable for low-volume operations and are commonly used in labs or specialty product lines.

Semi-automatic machines offer a balance between cost and efficiency by automating certain processes but still requiring some human intervention, such as container placement or triggering the fill cycle. They are often used by small to mid-sized businesses looking to increase output without investing in a full automation system.

Fully automatic machines, while more expensive, offer high-speed and high-volume capabilities with minimal labor. These systems are ideal for large-scale manufacturers that prioritize consistency, throughput, and reduced labor costs.

2. Type of Liquid

The viscosity and chemical properties of the liquid being filled can significantly affect machine design and price. Thin, water-like liquids require less specialized equipment than thicker, viscous, or corrosive liquids. For example, machines handling honey, oils, or gels may require piston or servo-driven pumps, while corrosive chemicals demand corrosion-resistant materials and enclosed filling systems to ensure safety and durability.

Additionally, liquids that foam or have high volatility, such as alcohol or bleach, require precise control mechanisms and filling nozzles that minimize splashing or evaporation, which adds to overall machine complexity and cost.

3. Filling Technology

Different filling methods, such as gravity filling, piston filling, overflow filling, and peristaltic filling, come with different price tags.

- Gravity fillers are commonly used for thin, free-flowing liquids and are generally more affordable.

- Piston fillers are ideal for thicker products and provide accurate, force-driven filling. They tend to be more costly due to their mechanical complexity.

- Overflow fillers are popular in the beverage and cosmetic industries because they deliver consistent fill levels and are excellent for transparent containers.

- Peristaltic fillers, often used in medical or pharmaceutical applications, offer sanitary filling and easy cleanup, but the precision and cleanliness come with a premium price.

Each technology serves a specific need, and the right choice depends on your product’s consistency, cleanliness requirements, and desired accuracy. Consult with experts to ensure you invest in a system that meets both performance expectations and budget constraints.

4. Production Speed & Volume Requirements

Higher production rates and larger batch sizes generally require more sophisticated machinery. Systems with multiple filling heads, automated conveyors, and integrated quality control systems support high-speed operations but also command a higher investment.

Low-speed operations may use single or dual-head machines, which are more budget-friendly and flexible but may not meet the needs of companies looking to scale quickly.

5. Number of Filling Heads

Machines with multiple filling heads increase output but also raise costs due to the added complexity. Filling heads determine how many containers can be filled simultaneously, impacting overall throughput.

For example, a machine with eight filling heads will process product significantly faster than one with two, but the upfront cost and maintenance requirements will be higher. Businesses must weigh the benefits of speed and scalability against their production volume and growth projections.

6. Container Types & Sizes

Machines need to be compatible with the container types and sizes used in your production. Customizable machines that can accommodate a wide variety of containers—ranging from small vials to large gallon jugs—are typically more expensive than standard models built for a single container type.

Additional container-handling features, such as adjustable guides, quick-change parts, or rotary indexing tables, can improve efficiency and flexibility but will influence overall cost.

7. Construction Materials

Stainless steel construction is often required for food-grade or pharmaceutical applications, which can add to the machine’s price. Machines made with corrosion-resistant or sanitary-grade materials command higher costs due to their durability and compliance with industry regulations such as the U.S. Food and Drug Administration (FDA), the U.S. Department of Agriculture (USDA), or Current Good Manufacturing Practice (cGMP).

Specialty finishes like polished welds, clean-in-place (CIP) systems, or dust-resistant enclosures further enhance performance in specific industries but also add to cost.

8. Additional Features & Integrations

Optional features such as bottle positioning systems, programmable logic controller (PLC) options, touch screen interfaces, and integration with other packaging machinery (cappers, labelers, conveyors, etc.) also affect pricing. Advanced controls allow for recipe storage, real-time diagnostics, and remote troubleshooting, which can be invaluable for complex operations.

While these features enhance productivity and reduce downtime, they also require a higher capital investment. Many businesses find that the long-term benefits justify the upfront cost through labor savings, improved accuracy, and reduced product waste.

Where to Buy a Liquid Filling Machine

Choosing the right supplier is just as important as choosing the right equipment. At E-PAK Machinery, we specialize in providing customizable, reliable, and efficient liquid filling solutions tailored to your industry and application. Our team works closely with clients to understand their production needs and recommend systems that deliver maximum performance and ROI.

We offer a wide selection of liquid filling machines, from entry-level tabletop models to fully integrated, automated packaging lines. With extensive experience across a range of industries—including food and beverage, chemicals, cosmetics, pharmaceuticals, and more—we’re equipped to help you scale your production with confidence.

Beyond equipment sales, E-PAK offers a full suite of services including machine installation, operator training, maintenance plans, and technical support. Our customer-centric approach ensures that you not only get the right machine but also the support and knowledge needed to maximize its value over time.

If you’re upgrading existing equipment or launching a new product line, E-PAK Machinery is committed to helping you succeed. Our machines are built in the U.S. with quality craftsmanship, and we pride ourselves on delivering long-term solutions.

Shop High-Quality Liquid Filling Machines at E-PAK Machinery

Understanding your specific production needs, container types, liquid characteristics, and growth plans will help you select a machine that aligns with both your operational requirements and budget. Investing in the right liquid filling machine can improve productivity, ensure consistent product quality, and scale your business efficiently.

Need help finding the right filling solution? We’re here to help.

E-PAK Machinery is a leader in the product filling industry, and we are proud to offer a wide variety of bottling machines, conveyors, and rotary turntables with the latest technological advancements and the most modern tools. Our goal is to provide you with high-quality and durable equipment that meets your unique packaging needs.

Contact us today to learn more about our full line of liquid filling machines and request a custom quote tailored to your business needs. Our experts are here to answer your questions, walk you through the selection process, and provide a solution that supports your success today and into the future.

Recent Posts

- Food Packaging Machine Price Guide: How Much Does a Food Packaging Machine Cost?

- What Are the Different Types of Food Packaging Machines?

- Food & Beverage Filling, Capping, & Packaging Machine Market Growth

- Small-Scale Food Packaging Machines: The Best Food Packaging Machines for a Small Business

- Automatic vs. Semi-Automatic Liquid Filling Machines: Which Option Is Right for Your Packaging Line?