Loading... Please wait...

Loading... Please wait...Types of Bottling Equipment for Water Bottle Filling Systems

Posted by Krys Beal on 12th Feb 2019

Water bottle filling systems require specific liquid filling machines during the packaging process. Drinking water has certain sanitation requirements that demand the use of liquid packaging equipment that can meet them, as well as machinery that can maintain optimal efficiency throughout the packaging process. Bottling equipment lines require a system of bottle cleaning equipment, liquid filling machines, conveyors, cappers and labelers for packaging.

Bottling Equipment Machinery and Consumables

When working with products that will ultimately be consumed—juices, waters, and more—the bottling equipment must be designed for safety. Highly sanitary conditions must be present in order to safely package these products, and it’s important that the machinery not only be easy to clean, but resistant to things like corrosion and bacteria buildup that can compromise the safety of your products. When you use machines, they need to be specifically tailored to the needs of consumable products.

Bottle Cleaning Machinery for Water Bottle Packaging

Before liquid filling can occur, water bottles need to be free of contaminants of any kind. Bottle cleaning equipment can ensure that water bottles are free of dust and other particles that can make drinking water unsafe for consumption. Packaging lines often utilize air rinsers to remove possible water contaminants, and they are designed to effectively clean water bottles of various shapes and sizes.

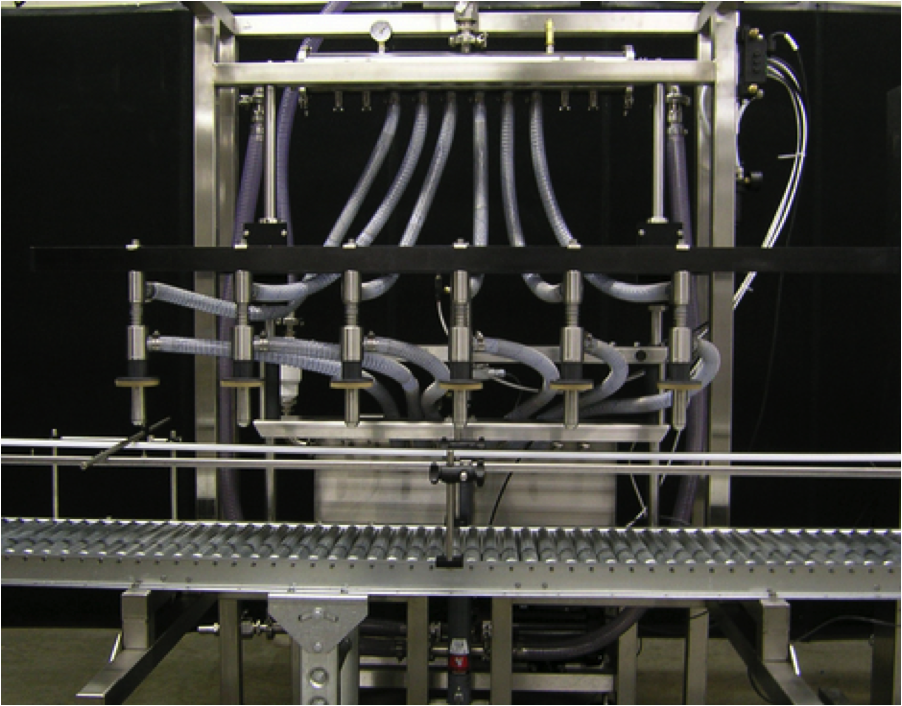

Liquid Filling Machines and Conveyor Bottling Equipment

After bottles have undergone thorough cleaning with air rinsers, the liquid filling process can begin with proper liquid bottling equipment. Packaging line operators can set-up and control most liquid filling machines with ease in order to maintain efficiency, and automated conveyors can bring bottles to each liquid filling station and carry them to the next station. Gravity fillers are typically used for products with a water-thin viscosity, which includes drinking water.

Capping Machines for Applying Water Bottle Caps

Once water bottles are filled, the next step is capping. Water bottles require airtight and watertight caps to prevent product contamination and leakage, and efficient capping machines can apply tight, sealed caps to water bottles of various heights and widths. Operators can adjust bottle capping equipment according to the size of the bottles, ensuring that they accurately apply each cap and tighten it.

Labeling Machines for Bottle Label Application

The final piece of equipment that water bottle filling systems require is a labeling machine. Bottle labelers can apply paper and clear labels to water bottles, accommodating for different heights and widths, as well as the general shape of the water bottle. Label applications are pressure-sensitive to prevent any damage to the bottle while applying labels that won't easily peel off.

Learn more about the various bottling equipment and machines used to create your favorite products by talking with us at E-PAK Machinery. We offer high quality packaging machinery for a variety of industries and products. If you’re interested in finding an efficient way to package your liquid product, using packaging machinery from E-PAK is a great way to do so. From bottle cleaners to liquid filling machines and more, we’ve got everything you need. Contact an E-PAK expert and let us help you.